John Humphreys

New LVC Member

So my 2003 3.9L Gen II has the fan constantly running on high, without the engine overheating and the temp gauge is on normal. The fan will slow down if I set the heater on full, but comes right back again when I turn off the heat.

From all the threads I've read on here, these are clear signs of air in the cooling system right?

Replaced the Degas bottle & cap, the radiator, all the radiator hoses (upper, lower, etc), all 3 pieces of the Thermostat housing, (Thank Soul!) fresh seals & o-rings. No signs of head gasket problems (No oil in the coolant or coolant in the oil). Note, the DCCV was just replaced 3 months ago, and I'm not seeing any signs of failure from the DCCV.

Bleed the system several times and nothing has changed, the fan is still running on high speed non stop!

I took it to a mechanic, complete flush and pressure tested the entire system. No leaks but the fan is still running on high.

So my questions are:

1) Any help in diagnosing the problem? I know the pressure test didn't show signs of leakage but it shows all the symptoms of it even after replacing all the "plastic parts".

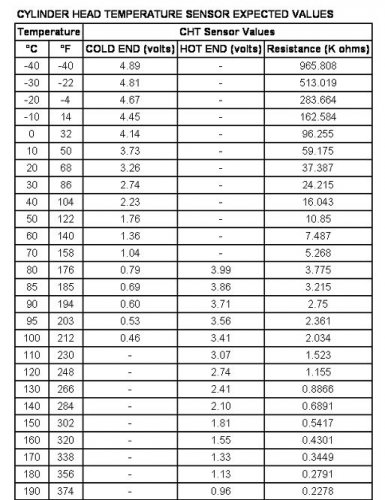

2) Any alternative ideas? Could be the ECT sensors but intake removal is over my head and I don't want to blow $500 and find out that's not the issue. I'm not getting any codes or faults on the MIL. Could it be a wiring or PCM issue?

3) If I do not fix this, what damage is this doing to my engine?

Thanks for any help!

From all the threads I've read on here, these are clear signs of air in the cooling system right?

Replaced the Degas bottle & cap, the radiator, all the radiator hoses (upper, lower, etc), all 3 pieces of the Thermostat housing, (Thank Soul!) fresh seals & o-rings. No signs of head gasket problems (No oil in the coolant or coolant in the oil). Note, the DCCV was just replaced 3 months ago, and I'm not seeing any signs of failure from the DCCV.

Bleed the system several times and nothing has changed, the fan is still running on high speed non stop!

I took it to a mechanic, complete flush and pressure tested the entire system. No leaks but the fan is still running on high.

So my questions are:

1) Any help in diagnosing the problem? I know the pressure test didn't show signs of leakage but it shows all the symptoms of it even after replacing all the "plastic parts".

2) Any alternative ideas? Could be the ECT sensors but intake removal is over my head and I don't want to blow $500 and find out that's not the issue. I'm not getting any codes or faults on the MIL. Could it be a wiring or PCM issue?

3) If I do not fix this, what damage is this doing to my engine?

Thanks for any help!