So I finished the angel eyes and here are some pics of them. They came out great, overall not as hard as I thought. The hardest part was cutting them open. The dremel part was easy, I just cut in deep enough to cut the black lip off, but then I had to use 2 flat heads to lift the headlight off from the black sealant to take apart, this was the harder part. The first headlight took me about 1.5 hrs to take apart and the second about 40-50 minutes since I had practice.

This is the silicone adhesive I used

http://www.liquidnails.com/products/product.jsp?productId=74

I cut around the top screw so I could use it again when trying to re-seal the headlight to hold it in place. The bottom part is an easy cut, just cut straight across it, no screws there or curves to follow.

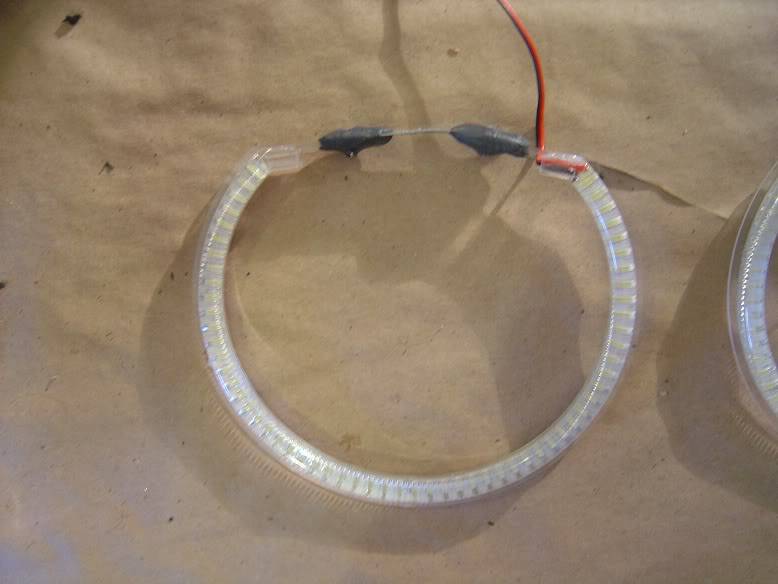

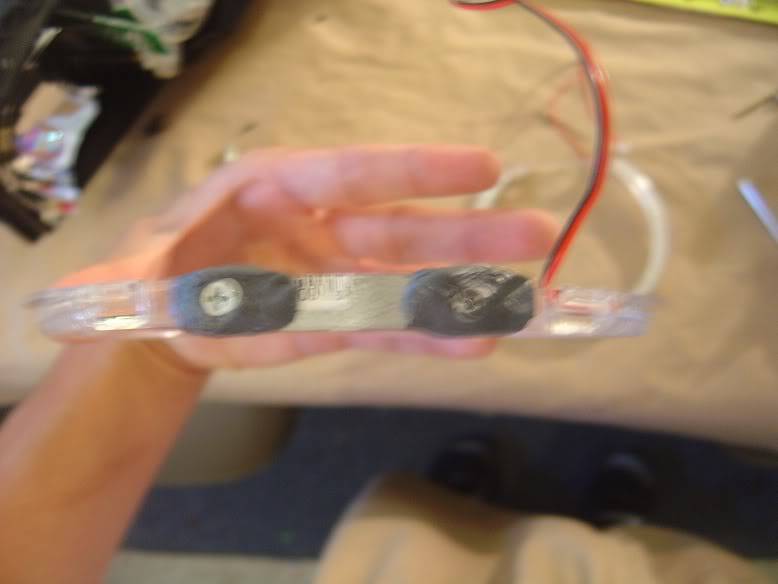

The size the big ring comes in is not the right shape or size to completely fill in the low beam‘s shape. I had to cut the little plastic that connects the 2 sides of the ring and jerry-rig something to make it stay. The guy from lightwurkz posted on here saying you might be able to get maybe 10mm if you cut this plastic, but I was able to spread them apart a total of about 1 ¼ inches, but I only needed about 1 1/8 to get the size of the big low beam ring. I drilled a hole on one side, put a piece of metal sheet I cut on it, spread it open carefully to not break it, marked where the hole would be on the other side to stay at 1 1/8 in open, and screwed it on that side too.I replaced the little long screws with tiny, tiny screws I had laying aroung so they wold not stick down that far. The screw alone would not keep it open straight, the ring would twist to the sides, it stayed open but not straight. What I did was put some quicksteel around the screw and metal sheet to keep the ring from twisting out of shape.

The metal sheet and quicksteel is not visible, it is covered by the benzel.

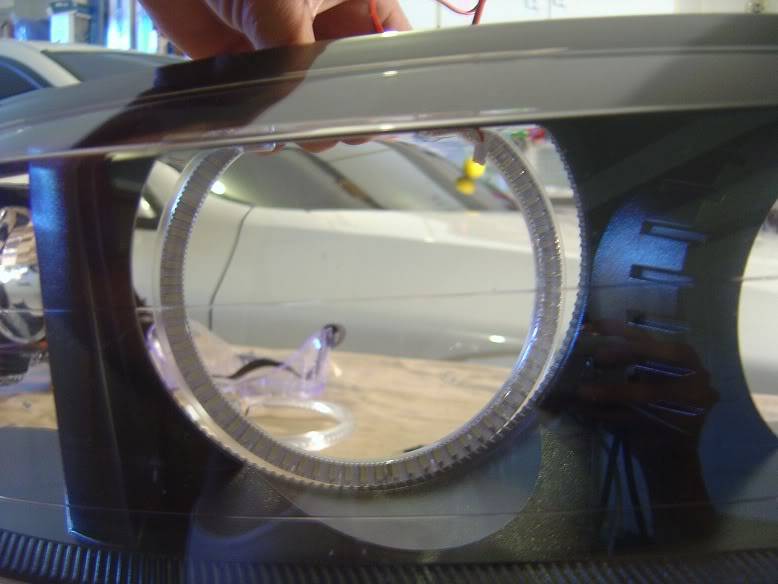

The rings were easy to mount. The big ring has a plastic lip on the edge which helped. I put some all purpose adhesive on the bottom half of the ring, on the lip where it touches the low beam part of the benzel. I applied more around the edge overlapping the ring and benzel to secure it. The low beam was easy; I just laid it on the hi-beam benzel hole and applied the adhesive on the edge of it.

This is how lightwurks does the install with the big ring, compare it too the way I did it with the ring cut apart to fill in the hole better.

This was taken after the rainy day. The all purpose silicone adhesive I used looks like it worked out great and sealed it up good. I drove 13 miles in the rain, I had no water inside at all, no foggy headlights, the adhesive worked great as a sealer.

The finished product!!!!! They are clearly visible in the day, they are super bright.I'm thinking they will look meaner with the eyebrows once they come back from the shop along with the lse bumper, but for now here it is.

This is the silicone adhesive I used

http://www.liquidnails.com/products/product.jsp?productId=74

I cut around the top screw so I could use it again when trying to re-seal the headlight to hold it in place. The bottom part is an easy cut, just cut straight across it, no screws there or curves to follow.

The size the big ring comes in is not the right shape or size to completely fill in the low beam‘s shape. I had to cut the little plastic that connects the 2 sides of the ring and jerry-rig something to make it stay. The guy from lightwurkz posted on here saying you might be able to get maybe 10mm if you cut this plastic, but I was able to spread them apart a total of about 1 ¼ inches, but I only needed about 1 1/8 to get the size of the big low beam ring. I drilled a hole on one side, put a piece of metal sheet I cut on it, spread it open carefully to not break it, marked where the hole would be on the other side to stay at 1 1/8 in open, and screwed it on that side too.I replaced the little long screws with tiny, tiny screws I had laying aroung so they wold not stick down that far. The screw alone would not keep it open straight, the ring would twist to the sides, it stayed open but not straight. What I did was put some quicksteel around the screw and metal sheet to keep the ring from twisting out of shape.

The metal sheet and quicksteel is not visible, it is covered by the benzel.

The rings were easy to mount. The big ring has a plastic lip on the edge which helped. I put some all purpose adhesive on the bottom half of the ring, on the lip where it touches the low beam part of the benzel. I applied more around the edge overlapping the ring and benzel to secure it. The low beam was easy; I just laid it on the hi-beam benzel hole and applied the adhesive on the edge of it.

This is how lightwurks does the install with the big ring, compare it too the way I did it with the ring cut apart to fill in the hole better.

This was taken after the rainy day. The all purpose silicone adhesive I used looks like it worked out great and sealed it up good. I drove 13 miles in the rain, I had no water inside at all, no foggy headlights, the adhesive worked great as a sealer.

The finished product!!!!! They are clearly visible in the day, they are super bright.I'm thinking they will look meaner with the eyebrows once they come back from the shop along with the lse bumper, but for now here it is.