oddball

Dedicated LVC Member

Cautions/Warning: This was developed and tested on my '02 V8 and should work for all Gen 1 vehicles. No guarantees or warranties of any kind. Test carefully, monitor temps directly and be careful. The electric fan can place a significant load on the alternator, so monitor your charging system closely.

I am proud to announce PCBs have finally been made so I can broadly offer these controllers. For-Sale thread:

http://www.lincolnvscadillac.com/fo...er-for-Gen-1-cars&p=2037303411#post2037303411

Some engineering background is in this thread: http://www.lincolnvscadillac.com/showthread.php?t=70387

This thread is focused on just an install and utilization of the controller. The only particularly new info is the install and calibration of the controller.

Sourcing Parts

Gen 2 fans can generally be found on eBay for $50 to $150. The controller can be made from the diagram in the other thread, or you can contact me via email at oddball at oddworld.org for pricing and availability. The only other parts are approximately 8 feet of 6ga red wire, 3 feet of 6ga black wire, 15 feet of signal wire (18ga to 22ga), an assortment of ring connectors and a fuse holder with a 60 amp fuse. Walmart has a good fuse holder.

Do NOT use less than 6ga wire for the power and ground to the fan!

Hydraulic Bypass

On the V8, the hydraulic pump can be entirely removed and a shorter (~100 inch) belt used. On the V6, the pump must remain due to belt routing. One user successfully gutted the pump so it acted like a pulley. Some users have also routed the pump back into itself. If you leave the pump in be very careful to ensure it does not seize.

Fan Install

Remove the old fan. Before installing the new fan, grind/cut all protrusions (except the mounting tabs!) off of the passenger side of the fan. It mounts in the same manner as the Gen 1 fan. The Gen 2 fan does not have mounting provisions for the aux pump, so you must zip tie or otherwise secure it appropriately.

The fan will have either two connectors ('03, '04) or one connector ('05, '06). In both cases the wiring is the same. The large black wire is the ground and can be run to the body bolt under the air filter box:

The large red wire is power. One good source is the main power feed to the engine bay power box:

I put the fuse holder behind the passenger headlight:

Remember that the power feed must have CONSTANT power - not switched. Do not use a relay feed or any existing fuse in the engine bay box as they will not be able to handle the fan load.

Run the two signal lines from the fan to the passenger fender. The Green wire on the fan is Fan Power and the White/Black is Fan Signal.

Controller Install

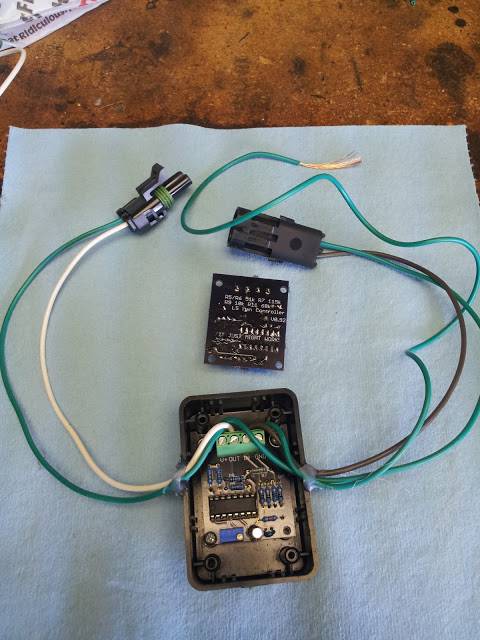

The controller has five wires: Ground, Power from PCM, Signal from PCM, Fan Power, Fan Signal. If sourced from me, the Ground and PCM lines come out one side while the Fan lines come out the other.

I like to use Weatherpack connectors, with opposite genders on each side.

Cut off the actuator connector for the hydraulic pump. Solder on two wires. The Green must go to Power from PCM, which is a green wire on my builds. The Brown must go to Signal from PCM, which is a brown wire on my builds.

(note that the extension wires are black in this picture)

The Ground can go just about anywhere. I used a body bolt by the shock mount.

The Fan Power must go to the Green wire to the fan, which is a Green wire in my build. The Fan Signal must go to the White/Black wire to the fan which is a White wire in my build.

The controller box can simply float beside/beneath the power box. Make sure it cannot fall into the accessory drive and isn't exposed to direct heat.

Test!

Start the car and turn off the climate control. If the engine is cool then the fan should spin somewhat and slow to a stop within a minute or two. Turn on the A/C and set to very cool to ensure the compressor engages. The fan should speed up to a notable breeze.

Proper testing requires an oscilloscope. Monitor the input signal and the output signal and ensure they match appropriately per the notes in the other thread.

Controller Calibration

My controllers are sold pre-calibrated and tested on my car. This should not be necessary under general use. This is also assuming a controller using the circuit design from the other thread. Calibration is only necessary if the fan attempts to spin up to full speed when it should be off. This is easily noticed as the fan will briefly spin up for a few seconds and immediately slow down, then speed up again, and slow down, etc.

My controller designs:

The potentiometer is the blue rectangle in the lower left corner.

This must be performed when the engine is COLD. Remove the cover from the controller Turn the key to Run and start the engine. Turn Off the climate control. Wait one minute. Using a small screwdriver turn the potentiometer clockwise in quarter turn increments while pausing for five seconds after each turn until the fan oscillates between stopped and full speed. Turn the potentiometer 3/4 of a turn clockwise.

Done!

If you notice that the fan occasionally engages full speed on very cold days then turn the pot one quarter turn clockwise.

Failsafe

If it appears the controller is not working and causing overheating, then bypass the controller by directly connecting the PCM connector to the Fan connector. This will cause the fan to run full speed whenever the key is on Run.

I am proud to announce PCBs have finally been made so I can broadly offer these controllers. For-Sale thread:

http://www.lincolnvscadillac.com/fo...er-for-Gen-1-cars&p=2037303411#post2037303411

Some engineering background is in this thread: http://www.lincolnvscadillac.com/showthread.php?t=70387

This thread is focused on just an install and utilization of the controller. The only particularly new info is the install and calibration of the controller.

Sourcing Parts

Gen 2 fans can generally be found on eBay for $50 to $150. The controller can be made from the diagram in the other thread, or you can contact me via email at oddball at oddworld.org for pricing and availability. The only other parts are approximately 8 feet of 6ga red wire, 3 feet of 6ga black wire, 15 feet of signal wire (18ga to 22ga), an assortment of ring connectors and a fuse holder with a 60 amp fuse. Walmart has a good fuse holder.

Do NOT use less than 6ga wire for the power and ground to the fan!

Hydraulic Bypass

On the V8, the hydraulic pump can be entirely removed and a shorter (~100 inch) belt used. On the V6, the pump must remain due to belt routing. One user successfully gutted the pump so it acted like a pulley. Some users have also routed the pump back into itself. If you leave the pump in be very careful to ensure it does not seize.

Fan Install

Remove the old fan. Before installing the new fan, grind/cut all protrusions (except the mounting tabs!) off of the passenger side of the fan. It mounts in the same manner as the Gen 1 fan. The Gen 2 fan does not have mounting provisions for the aux pump, so you must zip tie or otherwise secure it appropriately.

The fan will have either two connectors ('03, '04) or one connector ('05, '06). In both cases the wiring is the same. The large black wire is the ground and can be run to the body bolt under the air filter box:

The large red wire is power. One good source is the main power feed to the engine bay power box:

I put the fuse holder behind the passenger headlight:

Remember that the power feed must have CONSTANT power - not switched. Do not use a relay feed or any existing fuse in the engine bay box as they will not be able to handle the fan load.

Run the two signal lines from the fan to the passenger fender. The Green wire on the fan is Fan Power and the White/Black is Fan Signal.

Controller Install

The controller has five wires: Ground, Power from PCM, Signal from PCM, Fan Power, Fan Signal. If sourced from me, the Ground and PCM lines come out one side while the Fan lines come out the other.

I like to use Weatherpack connectors, with opposite genders on each side.

Cut off the actuator connector for the hydraulic pump. Solder on two wires. The Green must go to Power from PCM, which is a green wire on my builds. The Brown must go to Signal from PCM, which is a brown wire on my builds.

(note that the extension wires are black in this picture)

The Ground can go just about anywhere. I used a body bolt by the shock mount.

The Fan Power must go to the Green wire to the fan, which is a Green wire in my build. The Fan Signal must go to the White/Black wire to the fan which is a White wire in my build.

The controller box can simply float beside/beneath the power box. Make sure it cannot fall into the accessory drive and isn't exposed to direct heat.

Test!

Start the car and turn off the climate control. If the engine is cool then the fan should spin somewhat and slow to a stop within a minute or two. Turn on the A/C and set to very cool to ensure the compressor engages. The fan should speed up to a notable breeze.

Proper testing requires an oscilloscope. Monitor the input signal and the output signal and ensure they match appropriately per the notes in the other thread.

Controller Calibration

My controllers are sold pre-calibrated and tested on my car. This should not be necessary under general use. This is also assuming a controller using the circuit design from the other thread. Calibration is only necessary if the fan attempts to spin up to full speed when it should be off. This is easily noticed as the fan will briefly spin up for a few seconds and immediately slow down, then speed up again, and slow down, etc.

My controller designs:

The potentiometer is the blue rectangle in the lower left corner.

This must be performed when the engine is COLD. Remove the cover from the controller Turn the key to Run and start the engine. Turn Off the climate control. Wait one minute. Using a small screwdriver turn the potentiometer clockwise in quarter turn increments while pausing for five seconds after each turn until the fan oscillates between stopped and full speed. Turn the potentiometer 3/4 of a turn clockwise.

Done!

If you notice that the fan occasionally engages full speed on very cold days then turn the pot one quarter turn clockwise.

Failsafe

If it appears the controller is not working and causing overheating, then bypass the controller by directly connecting the PCM connector to the Fan connector. This will cause the fan to run full speed whenever the key is on Run.