girlfriendsls

LVC Member

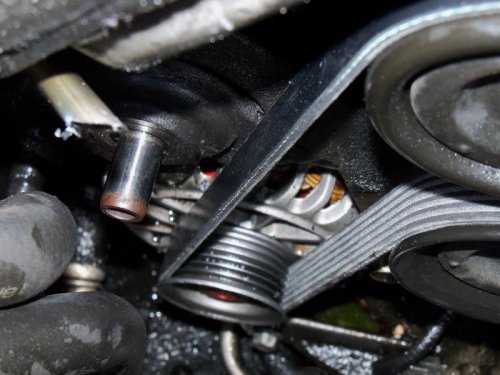

My girlfriend's 02 Lincoln LS V8 had a leaking hydraulic radiator fan system. What genius thought it would be a good idea to put a fluid system above the alternator?  The alternator shorted out and I had to replace it. That was fun to diagnose. Plus getting it out was like solving a puzzle.

The alternator shorted out and I had to replace it. That was fun to diagnose. Plus getting it out was like solving a puzzle.

I drive a '75 Ford Bronco, and Bronco owners often use the Taurus two speed, single electric fan, so I applied it to the LS. I also got some of my info from here and other threads:

http://www.lincolnvscadillac.com/forum/showthread.php?68306-Cooling-Fan-Replacement

If you have a lot of items that suck power, such as aftermarket amps, you might want to upgrade your alternator. I have had good experiences with eBay seller powermaxusa. However, I am running a stock alternator and stereo system.

Parts:

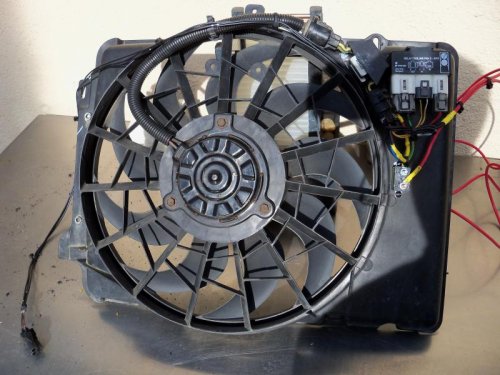

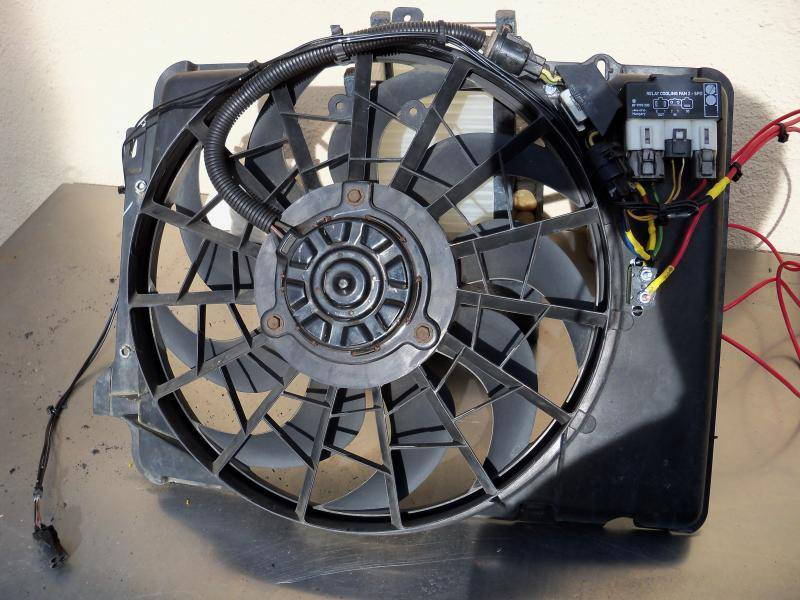

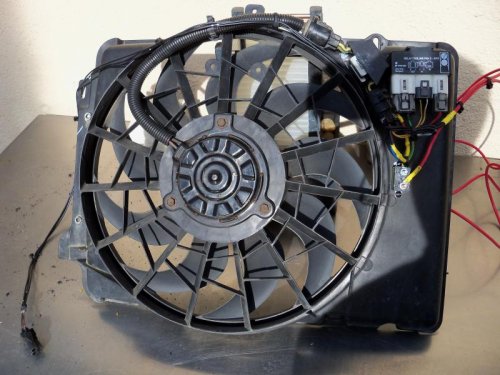

I went to the LKQ salvage yard on a half off day and pulled a radiator fan and fuses from a low mileage mid 90's Ford Taurus with the 3.8L V6. When searching numerous vehicles, I found it easiest to just look for the 3.8L V6 symbol on top of the engine. They also have a big, flat radiator cover plate. Be sure to test the fan before buying it.

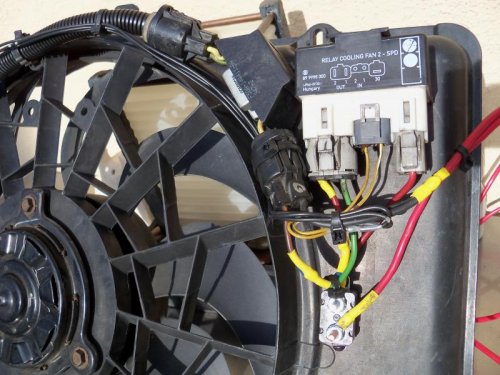

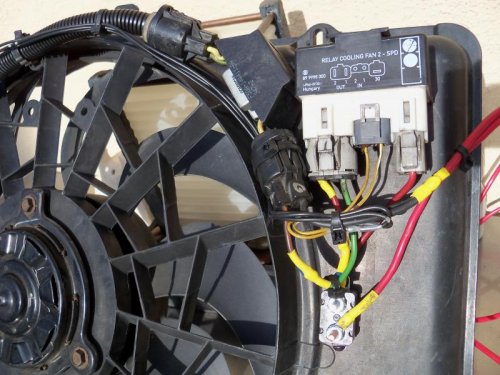

I pulled the fan controller and wiring off a mid 90's Volvo. It's usually attached to the top of the fan, under a cover. Get any mounting tabs, too. The Volvo fan will probably work as well as the Taurus fan, but the Taurus fan is easy to mount with little modification. Grab a spare fan controller while you are there, if you can find one.

I pulled a dual temp sensor and 90 degree connector wires from a mid 90's BMW. It is located on the passenger side of the radiator, near the top where it is easy to get to.

Total salvage yard cost, $40. I said it was all part of the single fan assembly.

I bought a 100 5/8" serpentine belt for about $40. Part #K061000/6K1000.

I bought a 50 amp relay and socket, a small fusible link and some 10 gauge wire.

Removal (note - I left the hydraulic fan pump in place):

Remove upper covers and air duct.

Remove upper radiator hose (passenger side), misc hoses and the hard tube that splits into each engine half (two bolts each side). Be careful when removing the tube, the seals will probably stay on the engine side.

Drain and remove the fan pump reservoir. Cut and plug/crimp pump line going to cooler (passenger side). Cut and plug/crimp fan line going to cooler (driver side). Cut the hard line going from the pump to the fan.

On the fan shroud, remove the one bolt holding the cylindrical canister, and the two bolts underneath it.

Remove the side bolts that hold the shroud in place.

Remove the upper radiator supports and carefully slide the fan/shroud upward and remove it. It might get caught on the cylindrical canister, I just cut off the shroud protrusions and it was clear. Replace the radiator supports.

Make a note of the serpentine belt routing and remove it.

Use a pulley remover to remove the hydraulic pump pulley. Leave the pump in place, no fighting stuck bolts, no removing the alternator, unless you really want to. I had recently replaced the alternator and didn't want to remove it again to get to the pump.

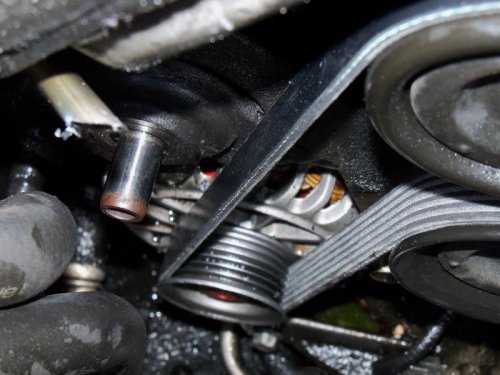

Clean the pulleys if they need it and install the new shorter belt. It will clear the hydraulic pump. The grooves will ride on the smooth idler above the hydraulic pump.

Assembly:

Mount the Volvo fan controller and fusible links to the fan shroud.

I didn't get many pics of it, but the wiring is fairly straightforward, this diagram shows the basic idea...

http://s214.photobucket.com/user/red04svtcobra/media/TaurusWire.png.html

From the fusible link go to the Volvo fan controller #30, the single red wire.

Connect the Volvo fan controller In 1 to the BMW temp sensor T1 (Low speed).

Connect the Volvo fan controller In 2 to the BMW temp sensor T2 (High speed).

Connect the Volvo fan controller Out 1 to the fan low speed.

Connect the Volvo fan controller Out 2 to the fan high speed.

Connect the grounds of the BMW temp sensor and fan to a single ground wire (10 gauge or higher).

Mount the fan:

Roughly place the fan. Position it to the driver side edge. Align the top of the shroud with the top of the radiator. Trim the top square on the driver side so it clears and sits flat on the edge (see pic). Trim the bottom corner so the hoses clear. Trim the side so it fits in the slot that the original shroud sat in. I matched the top mounting hole in the shroud to a hole in the radiator. Then I drilled a hole in the shroud to match a second hole in the radiator. Bolt in place when fit is right.

Install the temp gauge:

The hard coolant tube has a place that can be threaded for a temp sensor, such as on a Jaguar.

http://auto-lich.eu/img/Nummer/767_Jaguar_S_Type/1/2/Kuehlwasser_Schlaeuche1.JPG

On the Lincoln, it is just blocked off. I didn't have a M14 x 1.5 tap to do that. Plus it is a fragile glass/plastic material and I don't know how it will react. Plus I wanted the sensor to be lower. So I had to use a nut on a flat part.

Finding a M14 x 1.5 nut is difficult, so I cut off a piece of a matching lug nut. I painted it to at least make an effort to keep it from corroding.

I lined up the nut inside the tube, going as far back as I could while keeping it flat (make sure you leave room for the sensor and bolt). I marked the spot and drilled a pilot hole, eventually going up to a 1/2" hole. I wiggled the bit around until the hole was just large enough to screw in the temp sensor. Be very careful, the material is more fragile than you think.

I inserted the bolt. Then I used thermostat sealant on the threads/edges of the temp switch and lug nut and installed them. Be sure the sensor ground wire is facing you so that the 90 degree connector does not hit the engine (opposite of what I did here, oops).

Wipe off the top of the sensor so it is unobstructed.

Let it dry, attach the temp switch harness, and re-install the tube and hoses.

Power to system:

Finish the electrical wiring. Use a "key on" power signal to trigger a 50/30 amp relay - tap into the front power distribution box, relay #9, Wiper Run/Acc, top left pin, yellow/black stripe wire. I cut a hole in the side of the box and used a grommet for the two wires going to the external relay. You can try to use an empty socket in the box instead, but I couldn't get the pins to fit easily.

Page 188.

http://www.lincolnvscadillac.com/tech/Lincoln-LS/2002LincolnLS-OwnersManual.pdf

Have the relay switch connect the power distribution box side terminal (constant power) to the small fusible link on the fan shroud (10+ gauge wire).

Or, alternately (this makes more sense), go from the side terminal, to the fusible link, to the relay, and then to the fan controller #30.

Connect the ground wire for the relay and the ground wire from the fan/temp switch to a good ground. I found an empty hole just above the distribution box, so I removed the paint around it and used a bolt/nut and connector to secure the wires.

Re-install the air intake tube.

Fill/bleed your cooling system per spec. The heater bleed is important, the heater wasn't working before and started working after I bled it. I fixed that problem without even trying.

http://www.lincolnvscadillac.com/tech/Lincoln-LS/CoolingSystemDraining/

The low speed fan should come on after revving at 2k for a few minutes. It is rare for the high speed fan to come on, so it won't be much of a drain on the alternator.

Check for leaks. Replace the covers. Enjoy your cool new system! Get a back rub!

I'm open to any suggestions.

I drive a '75 Ford Bronco, and Bronco owners often use the Taurus two speed, single electric fan, so I applied it to the LS. I also got some of my info from here and other threads:

http://www.lincolnvscadillac.com/forum/showthread.php?68306-Cooling-Fan-Replacement

If you have a lot of items that suck power, such as aftermarket amps, you might want to upgrade your alternator. I have had good experiences with eBay seller powermaxusa. However, I am running a stock alternator and stereo system.

Parts:

I went to the LKQ salvage yard on a half off day and pulled a radiator fan and fuses from a low mileage mid 90's Ford Taurus with the 3.8L V6. When searching numerous vehicles, I found it easiest to just look for the 3.8L V6 symbol on top of the engine. They also have a big, flat radiator cover plate. Be sure to test the fan before buying it.

I pulled the fan controller and wiring off a mid 90's Volvo. It's usually attached to the top of the fan, under a cover. Get any mounting tabs, too. The Volvo fan will probably work as well as the Taurus fan, but the Taurus fan is easy to mount with little modification. Grab a spare fan controller while you are there, if you can find one.

I pulled a dual temp sensor and 90 degree connector wires from a mid 90's BMW. It is located on the passenger side of the radiator, near the top where it is easy to get to.

Total salvage yard cost, $40. I said it was all part of the single fan assembly.

I bought a 100 5/8" serpentine belt for about $40. Part #K061000/6K1000.

I bought a 50 amp relay and socket, a small fusible link and some 10 gauge wire.

Removal (note - I left the hydraulic fan pump in place):

Remove upper covers and air duct.

Remove upper radiator hose (passenger side), misc hoses and the hard tube that splits into each engine half (two bolts each side). Be careful when removing the tube, the seals will probably stay on the engine side.

Drain and remove the fan pump reservoir. Cut and plug/crimp pump line going to cooler (passenger side). Cut and plug/crimp fan line going to cooler (driver side). Cut the hard line going from the pump to the fan.

On the fan shroud, remove the one bolt holding the cylindrical canister, and the two bolts underneath it.

Remove the side bolts that hold the shroud in place.

Remove the upper radiator supports and carefully slide the fan/shroud upward and remove it. It might get caught on the cylindrical canister, I just cut off the shroud protrusions and it was clear. Replace the radiator supports.

Make a note of the serpentine belt routing and remove it.

Use a pulley remover to remove the hydraulic pump pulley. Leave the pump in place, no fighting stuck bolts, no removing the alternator, unless you really want to. I had recently replaced the alternator and didn't want to remove it again to get to the pump.

Clean the pulleys if they need it and install the new shorter belt. It will clear the hydraulic pump. The grooves will ride on the smooth idler above the hydraulic pump.

Assembly:

Mount the Volvo fan controller and fusible links to the fan shroud.

I didn't get many pics of it, but the wiring is fairly straightforward, this diagram shows the basic idea...

http://s214.photobucket.com/user/red04svtcobra/media/TaurusWire.png.html

From the fusible link go to the Volvo fan controller #30, the single red wire.

Connect the Volvo fan controller In 1 to the BMW temp sensor T1 (Low speed).

Connect the Volvo fan controller In 2 to the BMW temp sensor T2 (High speed).

Connect the Volvo fan controller Out 1 to the fan low speed.

Connect the Volvo fan controller Out 2 to the fan high speed.

Connect the grounds of the BMW temp sensor and fan to a single ground wire (10 gauge or higher).

Mount the fan:

Roughly place the fan. Position it to the driver side edge. Align the top of the shroud with the top of the radiator. Trim the top square on the driver side so it clears and sits flat on the edge (see pic). Trim the bottom corner so the hoses clear. Trim the side so it fits in the slot that the original shroud sat in. I matched the top mounting hole in the shroud to a hole in the radiator. Then I drilled a hole in the shroud to match a second hole in the radiator. Bolt in place when fit is right.

Install the temp gauge:

The hard coolant tube has a place that can be threaded for a temp sensor, such as on a Jaguar.

http://auto-lich.eu/img/Nummer/767_Jaguar_S_Type/1/2/Kuehlwasser_Schlaeuche1.JPG

On the Lincoln, it is just blocked off. I didn't have a M14 x 1.5 tap to do that. Plus it is a fragile glass/plastic material and I don't know how it will react. Plus I wanted the sensor to be lower. So I had to use a nut on a flat part.

Finding a M14 x 1.5 nut is difficult, so I cut off a piece of a matching lug nut. I painted it to at least make an effort to keep it from corroding.

I lined up the nut inside the tube, going as far back as I could while keeping it flat (make sure you leave room for the sensor and bolt). I marked the spot and drilled a pilot hole, eventually going up to a 1/2" hole. I wiggled the bit around until the hole was just large enough to screw in the temp sensor. Be very careful, the material is more fragile than you think.

I inserted the bolt. Then I used thermostat sealant on the threads/edges of the temp switch and lug nut and installed them. Be sure the sensor ground wire is facing you so that the 90 degree connector does not hit the engine (opposite of what I did here, oops).

Wipe off the top of the sensor so it is unobstructed.

Let it dry, attach the temp switch harness, and re-install the tube and hoses.

Power to system:

Finish the electrical wiring. Use a "key on" power signal to trigger a 50/30 amp relay - tap into the front power distribution box, relay #9, Wiper Run/Acc, top left pin, yellow/black stripe wire. I cut a hole in the side of the box and used a grommet for the two wires going to the external relay. You can try to use an empty socket in the box instead, but I couldn't get the pins to fit easily.

Page 188.

http://www.lincolnvscadillac.com/tech/Lincoln-LS/2002LincolnLS-OwnersManual.pdf

Have the relay switch connect the power distribution box side terminal (constant power) to the small fusible link on the fan shroud (10+ gauge wire).

Or, alternately (this makes more sense), go from the side terminal, to the fusible link, to the relay, and then to the fan controller #30.

Connect the ground wire for the relay and the ground wire from the fan/temp switch to a good ground. I found an empty hole just above the distribution box, so I removed the paint around it and used a bolt/nut and connector to secure the wires.

Re-install the air intake tube.

Fill/bleed your cooling system per spec. The heater bleed is important, the heater wasn't working before and started working after I bled it. I fixed that problem without even trying.

http://www.lincolnvscadillac.com/tech/Lincoln-LS/CoolingSystemDraining/

The low speed fan should come on after revving at 2k for a few minutes. It is rare for the high speed fan to come on, so it won't be much of a drain on the alternator.

Check for leaks. Replace the covers. Enjoy your cool new system! Get a back rub!

I'm open to any suggestions.