Madme

LVC Member

Well it all started with my 1989 Plymouth Voyager. I wasn't really planning to mod my Town Car but wanted to work on a new project. If you 've owned a 90 to 94 TC you all know how the lighting is. So I bought some projectors.

I bought a pair of BMW HID bi-xenon projectors and a pair of P6 fog lights

I started to bolt them both together. I figured it would be easyer to do this and to make them both fit in the headlight housing. It also ended up that the fog light is deeper than the Bi-xenon.

Insted of using a dremel to cut out the back which is loud and messy I used my soldering gun with a cutting tip.

Here I used galvanized strapping to make my brakets. Easy to bend and play with.

For the front lenses, using my soldering gun with the cutting tip, I cut out the top part of the factory lens cover.

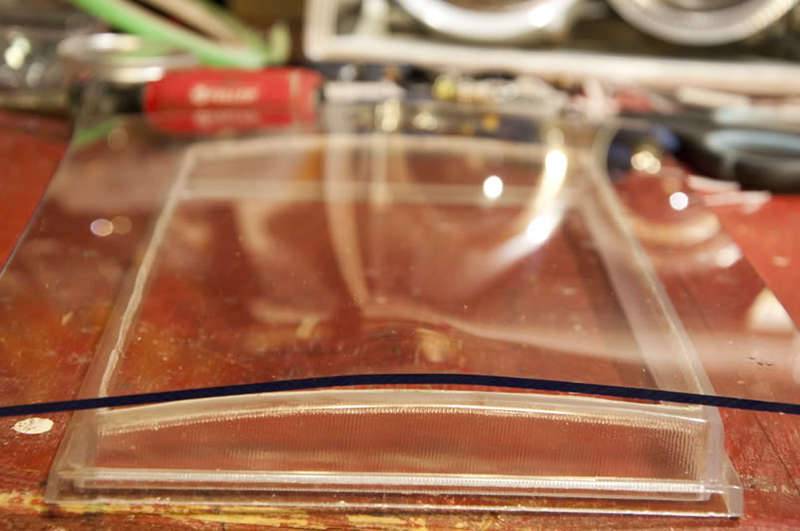

To make the bend in the plexiglass I put a piece on top of the lens frame and taped the corners down pulling the plexi down and making it curve. Then using a heat gun, heated the plexi until i started to warp then let cool down before I removed the tape.

For sealing the back I used stove pipe take and pieces of plexi to build it up. At first I was just going to use the tape but putting pieces of plexi made it more tough and easier to handle.

To install the new lights I need to cut out the fiberglass part.

The inner lights are 4100K HID and the outter ones are 8000K.

I'm using the fog lights as Daytimes

I bought a pair of BMW HID bi-xenon projectors and a pair of P6 fog lights

I started to bolt them both together. I figured it would be easyer to do this and to make them both fit in the headlight housing. It also ended up that the fog light is deeper than the Bi-xenon.

Insted of using a dremel to cut out the back which is loud and messy I used my soldering gun with a cutting tip.

Here I used galvanized strapping to make my brakets. Easy to bend and play with.

For the front lenses, using my soldering gun with the cutting tip, I cut out the top part of the factory lens cover.

To make the bend in the plexiglass I put a piece on top of the lens frame and taped the corners down pulling the plexi down and making it curve. Then using a heat gun, heated the plexi until i started to warp then let cool down before I removed the tape.

For sealing the back I used stove pipe take and pieces of plexi to build it up. At first I was just going to use the tape but putting pieces of plexi made it more tough and easier to handle.

To install the new lights I need to cut out the fiberglass part.

The inner lights are 4100K HID and the outter ones are 8000K.

I'm using the fog lights as Daytimes