Well, on Wednesday October 30, I finally got a day off from work so I finally took my car to the auto hobby shop to do the J mod. I took my sweet time and I have some very important pointers that were never mentioned in any of the write ups on the J mod. I will post descriptions above the pictures for easiest reading and no wall of text.

Tools that you need to make this job as easy as possible are listed here:

good set of snap ring pliers

5 or 6 inch C clamp, the thinner the better, there is not much room to use a larger clamp.

1/4 inch air impact or a nice 19.2 volt impact driver would be ideal

a 1/2 inch drill that can accept 29/64th drill bit, my drill is only a 3/8 and my Harbor Freight bits do not have reduced shanks to fit (the drill is to install a drain plug in the pan, I bought a universal 1/2-20 plug) Ran out of time to install the drain plug

8mm and 10mm sockets and 4 or 6 inch extension

inch pound torque wrench

razor scraper

I will skip the drain pan removal and the easy stuff and get to the meat of the job. Pictures will start right now.

These are the parts set up, gaskets and J mod write up and the drilled separator plate bought from

http://www.robstireandauto.com/products.html I only paid $45 shipped because all I needed was the predrilled plate

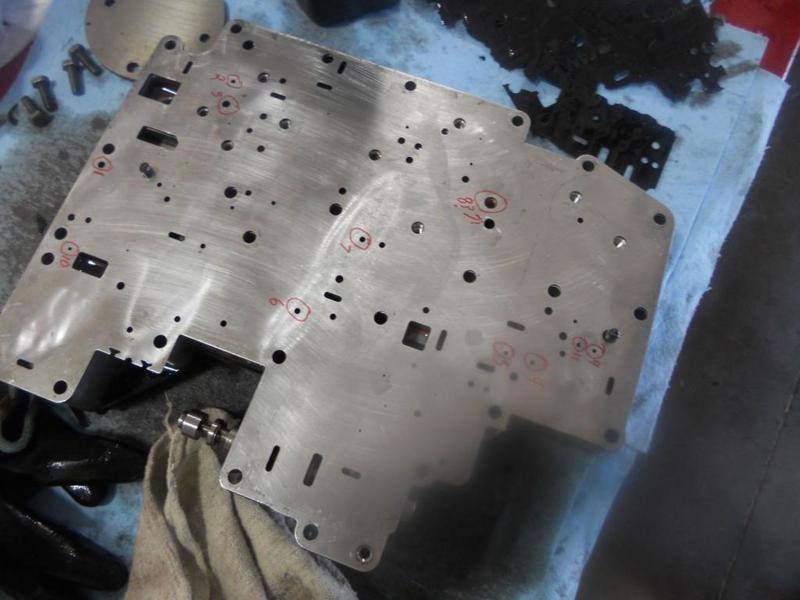

I have to send back my original undrilled plate. I circled all the holes that needed drilled and made sure they were all drilled out correctly.

Plate with numbers circled to make sure all holes were correctly drilled, I ordered a 1995 300 hp spec sep plate.

Make sure that bracket, the rooster comb and shifter valve are memorized in the proper place so you can put the valve body back without any problems

This picture shows the four electrical connectors in their proper place but this is really fool proof because the wire harness is perfectly matched so you can't really plug in the wrong connectors. Better safe than sorry, I always say.

Another shot of the rooster comb and connectors and shifter valve thing

Valve body removed, notice the 1-2 accumulator piston cover is still intact and so is the 2-3 accumulator piston cover. It is way easier to remove the snap ring holding the 1-2 piston assembly in with the valve body removed.

Here is the part that had me stuck for awhile as I tried to figure out why the heck it was so much harder to get the 1-2 piston assy' back into the bore. As you can see, the bore is tapered, so my piston kept getting stuck on the lip up top. In order to install the piston, it has to be installed straight up into the tapered area of the bore or you'll never get the piston assy' installed. I used a 6 inch long 1/2 inch extension with a 22mm socket under the piston and put it into the bore as straight as possible and it went all the way up into its bore. My piston was in good shape and both springs were not broken. The upper spring was orange and the bottom was purple. I replaced both springs with 2 purple ones. Once the piston is in its bore, its easy to install the lower spring and cover. Gently use the C clamp to keep it in its bore while you reinstall the snap ring.

This is the original 1-2 piston and the original springs with a new spring, the other purple spring was on another bench. Notice the old style 2-3 piston in the back ground. Also notice the two 8mm bolts with the bracket and rooster comb wheel in the back ground.

This is the new style 2-3 piston next to the original. Notice the 2-3 piston cover in the picture. I did not have to bend any tabs to keep the 2-3 piston in place, the cover had plenty of tightness. I left the lower spring out as suggested by everybody. Don't forget to lube up the new pistons with fresh Mercon V.

This is the sep plate with holes circled just to make sure it matches up with the TCCOA article pictures. All holes checked out. Number 10 is the larger reverse engagement and it now goes into reverse right away, no lag.

Valve body assembly removed and ready for surgery. Memorize the Pac man shaped discs but I think they only go a certain way. I just laid them out like I took them off to be 100 percent.

Separator plate and Pac Man reinforcement discs removed. This was a pretty gay part of the job, gasket removal. You will need a good razor blade or razor scraper to make life easy. I only had a few areas that were hard to remove but from the valve body. Since I have a new predrilled sep plate, I didn't have to remove the old gasket from the sep plate. I guess Rob will have to do that when I send in my sep plate. Make sure none of the old gasket has fallen into the little mazes in the valve body. If they do, make sure you pick it out.

This is the new sep plate ready to get bolted onto the valve body. Make sure you use fresh Mercon V to wet the gaskets as you put it onto the separator plates. Next you just have to reinstall the Pac Man discs and torque everything to 92 inch pounds.

DON'T FORGET the single 10mm bolt that helps secure the sep plate to the valve body. I kept the valve body up the whole time to prevent screens and check balls from falling out. The fluid inside was pretty fresh so I didn't really have to clean the valve body.

Finally, when you're ready to reinstall the valve body, make sure you grab one of the longer 8mm bolts that goes into the reinforcement plate on the valve body. The outer perimeter of the valve body uses slightly shorter bolts because of the plate. Line up the valve body and start the bolt into one of the center bolt holes so that you do not have to keep holding up the valve body. Make sure the shifter valve spool thing is in the proper position as you install this first bolt. Hand tight it so that its mostly tightened and then you can hand tighten the rest of the 8mm bolts all around the valve body. Once all bolts are hand tightened, use the tightening sequence picture in the TCCOA article and tighten them all down to 92 inch pounds. Don't forget where the one bracket and the one bolt holding the rooster wheel goes. You will see this clearly as you're doing it, its hard to explain. Make sure all bolts are accounted for, install a new trans filter, making sure the old O ring isn't in the hole. Mine was still in so I just pulled it out with a pick, be gentle and don't nick the soft aluminum. Don't forget to reinstall the 4 electrical connectors. Put the pan back on and tighten the 10mm bolts.

Because I spent 4.5 hours doing this, most of my old fluid drained out. I had to put in 8 or 9 quarts to get the level to right in the middle of the cross hatches on the hot part of the dip stick.

Test drive and enjoy your hard work. The shifts are definitely quicker and smoother but not too firm. When I did the Bauman shift kit in my first 95 Mark Viii, I had to change out some valves and springs and did my own plate drilling. That tranny shifted way firmer and harder than this J mod. I'm thinking of removing the lower 1-2 piston spring to see how I like it. I ran out of time so I didn't get to install my drain plug. I'll have to drop the pan soon to do this mod and may or may not remove the lower spring. It's a lot more responsive and I'm sure my gas mileage will get much better due to the quicker shifts.

Hope this write up will help people in the future. Here is a shot of my car in my front yard.