Gearheadloco

LVC Member

Hi Folks,

I've been re-building the Jaguar-designed, Ford manufactured 3.9l V8 engine in a 90K miles 2001 Lincoln LS that I bought for a princely $200! The previous owner of the car drove it with too little oil which resulted in the engine spinning two connecting rod bearings. I've rebuilt a number of engines in the past but never a Jaguar design, so I've been stumbling through the procedures using the 2001 Ford/Lincoln LS service manual as well as a 2000 Jaguar S-type manual for the 4.0l of this engine.

There are a number of excellent videos on youtube showing folks replacing some of components of the 3.9l/4.0l timing system, but it's not entirely clear from these videos nor the service manuals how the special tools are used and how things go together. So here's my attempt to document the process for the next lad - or lady - attempting to do the same thing -

I suppose you could do this job without these three special tools, but frankly they aren't that expensive and they are readily available so I wouldn't attempt this project without them.

First is special tool 303-645, the "Crankshaft Setting Tool." I got my Black Dog Manufacturing version from Amazon. This special tool fits in a position normally occupied by a sensor that senses the rotational RPM of the engine's flywheel. The flywheel has a series of square openings that generate an electronic pulse as it spins near the sensor. Cleverly, exactly ONE of those square openings has a rounded side that this tool inserts into perfectly. To insert the tool the crankshaft is rotated by hand (clockwise) until the crankshaft key-way is at six o'clock. This aligns this special flywheel sensor hole to a position where special tool 303-645 can be inserted. Once inserted, the crankshaft can't spin and cylinder 1 is set at 45 degrees after top dead center (ATDC).

Here's my engine with the 303-645 installed. You can see the rectangular holes near the special hole that takes the tool:

And here you can see the tool inserted into the special hole that has a different shape from all of the rest:

OK, now your engine is locked in the correct position for timing. But if you have done a complete re-build your four camshafts (two intake with the giant counterweights, and two exhausts) are in random rotational locations and are not timed to the crankshaft.

Jaguar takes a novel approach - there aren't any timing notches or dots or anything that would help you understand their correct positioning in relation to the crankshaft. BUT you have special tool 303-530 to help you here. If you examine your camshafts near their forward (front of engine) end, you will notice that each camshaft has a flat section between the first and second camshaft journals. Special tool 303-530 is your friend here, as it bolts to the head and holds both the intake and exhaust camshafts in a fixed location (as is the crankshaft) so that you can string your new timing chains (small chain from intake to exhaust, and large chain from crankshaft to intake camshaft). Here's the tool I bought from Amazon, also from Black Dog Manufacturing -

You need to start with the left cylinder bank and head (left as viewed from the driver's seat) because it's long crankshaft chain sits behind the right head's similar chain. I forgot to take a picture as I was doing the left head, so here's special tool 303-530 installed on my right bank:

In this picture you can see how the special tool clamps down on the flattened region on the intake (top) and exhaust (below) camshafts on the right head:

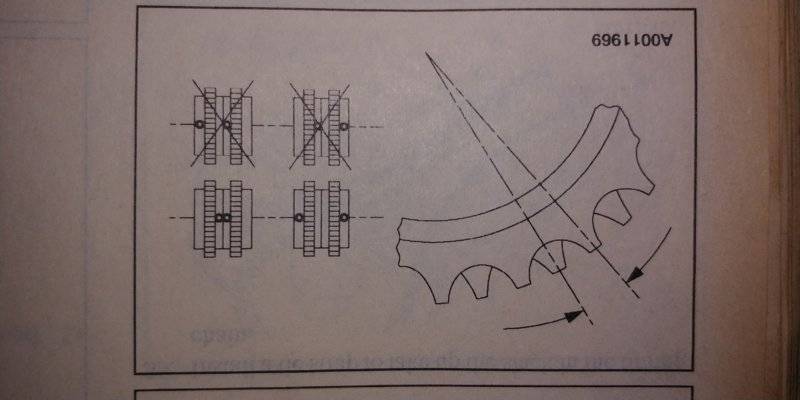

As you install the small timing chains between the camshafts and the larger chain from intake camshaft to the crankshaft, keep careful note on the crankshaft sprocket - especially if your engine has two separable crankshaft sprockets as mine does. My understanding is that later year engines use a single piece crankshaft sprocket with teeth for both heads. With my 2001 engine, their are two identical sprockets, each with an orientation dot. For proper timing the two sprockets MUST be installed with the two dots either adjacent to one another OR opposite each other. This spaces the teeth of one sprocket to be one half of a tooth behind (or ahead) of the other sprocket. The Ford/Lincoln manual has a good drawing of this:

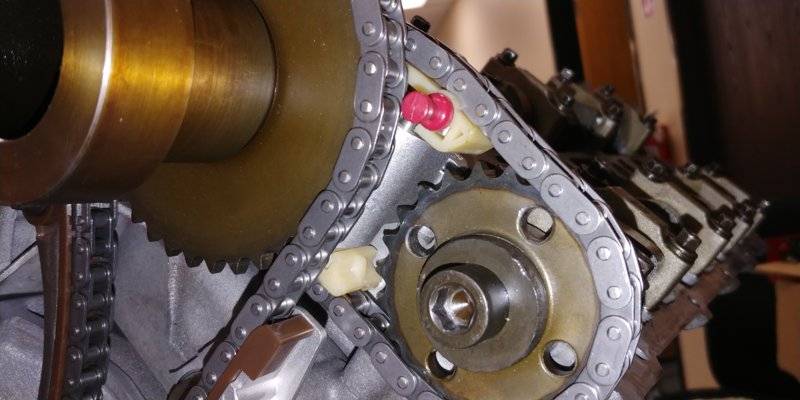

Here's what it looks like with both chains installed at the crankshaft. In my case my two crankshaft sprockets have their dots "touching" each other as in the lower left "OK" configuration in the factory manual above:

There is one other tool that isn't absolutely essential in this process, but it is very helpful!! This is special tool 303-532 that I also got from Amazon.

This tool engages two of four holes distributed around the exhaust camshaft sprocket and helps if you need to spin the two camshafts on each head together to get them ready to install the camshaft locking tool 303-530. Since I was doing a complete rebuild, I installed the small camshaft chain between the camshafts while they were still on the workbench. Then I carried them over as a unit - the two camshafts with the chain between them, and re-installed them into the head.

The process of installing the timing chains, guides and tensioners is fairly straightforward and covered pretty well in the manual and on youtube. So to wrap things up here are some pictures of my engine when everything was installed. It really isn't too hard if you go slow and take your time. This is a CRITICAL procedure and you can do severe damage to your engine if you get it wrong, but hopefully my pictures help a little if you decide to give it a try.

Phil in San Diego

Now back to work putting all of these new parts on this thing!

I've been re-building the Jaguar-designed, Ford manufactured 3.9l V8 engine in a 90K miles 2001 Lincoln LS that I bought for a princely $200! The previous owner of the car drove it with too little oil which resulted in the engine spinning two connecting rod bearings. I've rebuilt a number of engines in the past but never a Jaguar design, so I've been stumbling through the procedures using the 2001 Ford/Lincoln LS service manual as well as a 2000 Jaguar S-type manual for the 4.0l of this engine.

There are a number of excellent videos on youtube showing folks replacing some of components of the 3.9l/4.0l timing system, but it's not entirely clear from these videos nor the service manuals how the special tools are used and how things go together. So here's my attempt to document the process for the next lad - or lady - attempting to do the same thing -

I suppose you could do this job without these three special tools, but frankly they aren't that expensive and they are readily available so I wouldn't attempt this project without them.

First is special tool 303-645, the "Crankshaft Setting Tool." I got my Black Dog Manufacturing version from Amazon. This special tool fits in a position normally occupied by a sensor that senses the rotational RPM of the engine's flywheel. The flywheel has a series of square openings that generate an electronic pulse as it spins near the sensor. Cleverly, exactly ONE of those square openings has a rounded side that this tool inserts into perfectly. To insert the tool the crankshaft is rotated by hand (clockwise) until the crankshaft key-way is at six o'clock. This aligns this special flywheel sensor hole to a position where special tool 303-645 can be inserted. Once inserted, the crankshaft can't spin and cylinder 1 is set at 45 degrees after top dead center (ATDC).

Here's my engine with the 303-645 installed. You can see the rectangular holes near the special hole that takes the tool:

And here you can see the tool inserted into the special hole that has a different shape from all of the rest:

OK, now your engine is locked in the correct position for timing. But if you have done a complete re-build your four camshafts (two intake with the giant counterweights, and two exhausts) are in random rotational locations and are not timed to the crankshaft.

Jaguar takes a novel approach - there aren't any timing notches or dots or anything that would help you understand their correct positioning in relation to the crankshaft. BUT you have special tool 303-530 to help you here. If you examine your camshafts near their forward (front of engine) end, you will notice that each camshaft has a flat section between the first and second camshaft journals. Special tool 303-530 is your friend here, as it bolts to the head and holds both the intake and exhaust camshafts in a fixed location (as is the crankshaft) so that you can string your new timing chains (small chain from intake to exhaust, and large chain from crankshaft to intake camshaft). Here's the tool I bought from Amazon, also from Black Dog Manufacturing -

You need to start with the left cylinder bank and head (left as viewed from the driver's seat) because it's long crankshaft chain sits behind the right head's similar chain. I forgot to take a picture as I was doing the left head, so here's special tool 303-530 installed on my right bank:

In this picture you can see how the special tool clamps down on the flattened region on the intake (top) and exhaust (below) camshafts on the right head:

As you install the small timing chains between the camshafts and the larger chain from intake camshaft to the crankshaft, keep careful note on the crankshaft sprocket - especially if your engine has two separable crankshaft sprockets as mine does. My understanding is that later year engines use a single piece crankshaft sprocket with teeth for both heads. With my 2001 engine, their are two identical sprockets, each with an orientation dot. For proper timing the two sprockets MUST be installed with the two dots either adjacent to one another OR opposite each other. This spaces the teeth of one sprocket to be one half of a tooth behind (or ahead) of the other sprocket. The Ford/Lincoln manual has a good drawing of this:

Here's what it looks like with both chains installed at the crankshaft. In my case my two crankshaft sprockets have their dots "touching" each other as in the lower left "OK" configuration in the factory manual above:

There is one other tool that isn't absolutely essential in this process, but it is very helpful!! This is special tool 303-532 that I also got from Amazon.

This tool engages two of four holes distributed around the exhaust camshaft sprocket and helps if you need to spin the two camshafts on each head together to get them ready to install the camshaft locking tool 303-530. Since I was doing a complete rebuild, I installed the small camshaft chain between the camshafts while they were still on the workbench. Then I carried them over as a unit - the two camshafts with the chain between them, and re-installed them into the head.

The process of installing the timing chains, guides and tensioners is fairly straightforward and covered pretty well in the manual and on youtube. So to wrap things up here are some pictures of my engine when everything was installed. It really isn't too hard if you go slow and take your time. This is a CRITICAL procedure and you can do severe damage to your engine if you get it wrong, but hopefully my pictures help a little if you decide to give it a try.

Phil in San Diego

Now back to work putting all of these new parts on this thing!

Last edited: