Hello everyone. i would 1st off like to say thank you to all those who run this page and its members.

Ive been saved countless times n still is the #1 location 4 all Ls related material.

With that being said im finally starting my thread .

I own a 2005 Lincoln Lsv8 Ultimate.

All cooling has been overhauled n soon will be doing motor cleanup.

But as i was waitng and cold weather catchin up, i had started my headlight upgrade/retrofit.

Ive aquired a few headlights as spares over the years thru trades, i had an extra set of halogen housings with another to fix my cracked stock hid housing.

Me being me, they allll came apart lol

After seeing what was salvageable between all the headlight housings ive sucessfully have 1 hid housing n 1 halogen.

At 1st i was going to be retrofitting my hid housings with quad projectors. But after actually breaking them down and seeing the differences between the 2 i decided to retrofit halogen housing and be able to sell the hid housings. Theres no need to trash nice expensive headlights when halogen housings are the same. just different bowl and wiring + ballast.

I also have a video on youtube explaining the differences between halogen and hid housings for gen 2.

Now to the fun stuff... I kno for a fact i wanted clear corners on my headlights.

Amber/orange was definatly messin up my flow on how i wanted my car to look.

shout out to Manoli 4 the insight.

the reflector lens is behind that black plate with the l.e.d window. 2 strips of sealant hold the plate on. You can cut them off, and jb weld back on. no problem.

material used. plastic ceiling light panel. think 4x2ft sheet.

Next was the switchback halo install on both sets of headlight bezels (inside plastic trim)

Amazon.com: Mihaz Color White-Amber LED DRL Tube Light Car Switchback Soft FluxBeam with Signal-Sync for Headlights and Grills: Automotive

went with 2x pair of these per set.

Install easy... once u get tubes. u peel both ends off n pull led strip right out of the silicone tube. that way your able to mold a nice tight oem effect.

Then once tubes are all shapped up and look proper you can cut led strip and slowly feed it back in tubes. strips are cutable every 3 leds.

Picture has said clear corner and cover

also something i wanted to point out is with these specific led tubes, the top (opposite frm mounting hardware supplied) has most output.

And if you look real closely at the low beam circle you can see i mounted brackets to face out. instead of inside., firing toward one another. but later on my second set. I ditched mounting hardware and just siliconed everything in. less tedious.

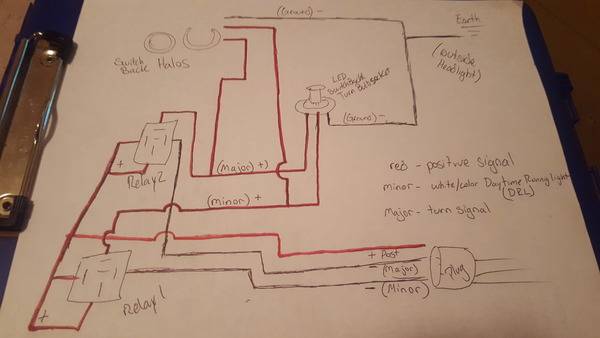

Now on to the wiring and making it all work.

ive came up with a nice detailed diagram of how to wire 2 relays (5pin but only use 4)

1 thing that I MUST!!!!! LET YOU KNOW!!!!

using the cheap brand of switchback bulb that i got. with the halo rings/tubes will not work together. lol

havent pinpointed it. turn signals all fuction in sequence and halos take over as daytime running light DRL

Even when i had halos running on seperated 12v. nothing. same result. even wired up relays with different 12v source n same. so theres gotta be feedback somewhere. its probably super simple.

switchback bulb by itself. wrks flawless... halos n tubes wrk flawless. them together? lol not so much but im totally digging the outcome. its only a tiny flaw in my eyes.

now this is the led that goes behind clear corner. i figured. hey. its got to be white. reflector was super amber. but no. you can either not use it at all... or you can do like i am n solder in white micro leds.

i need to get full done, done pictures of it all but last minute led swap kinda held me up lol.

I have this video so far of the overall operation without the led conversion here

Now i suppose we can get on to the real fun part. the quad projector project.

Welllll..... wasnt fun for me.

taking the bowl out and trying to use wat i can stock wise to have my adjusters work was a must.

I started makin room to fit projectors.

Started with 2.5 frm the retrofit source. believe its acme h1 bi-xenon

neck didnt fit at all so hada make room for that

after cuting out the center on high beam bowl, projector fits fine. bolt actually locks in frm backside and u twist on. i finally threw some jb weld jus to be sure on inside of bowl.

now on to the low beam. FDR n I have been noticing how kinda the low beam actually sits lower. u can see now bttr with projectors in

I also threw on the lens to test fit that high beam projector. kind of stuck out but i got clearance with no touching. hopefully ill be alright. i dont use high beams much anyway.

Big bummer on low beam.really wasnt gona stop me now. I guess nxt step would 1. get it to an ideal looking location inside bezel and 2. try n be level with high beam

so that stock adjusters can be used sucessfully

After jus looking at the bowl i knew making a plate to mimic stock adjusters would be best to fit n lift projector up. but still be even

This is wat i came up with. made a plate that fit inside of bowl. i had also cut bowl at bottom to line up straight because of the angle bowl is originally at would have projector aimed high.

i also cut backside of bowl to give me room to wrk and figure rear mount location.

And i j.b welded the Bleeep out of the plate.

Lmfao of course inside as well.

And after

Id have to say im much more happier...

so i get a cheap hid h1 kit to wire everything up n check cutoffs before i seal everything all up.

So far everything has been by eye and done in the house... found an extra set of h.i.d ballast covers n they work well for me.

now to check it all out.

I know, I know. dont laugh. it was all an eye ball. but so far thats where i stand. high beam n low beam are dead on. just need to rotate my low beams so cutoff is nice an crispy.

Stay tuned for part 2.

Ive been saved countless times n still is the #1 location 4 all Ls related material.

With that being said im finally starting my thread .

I own a 2005 Lincoln Lsv8 Ultimate.

All cooling has been overhauled n soon will be doing motor cleanup.

But as i was waitng and cold weather catchin up, i had started my headlight upgrade/retrofit.

Ive aquired a few headlights as spares over the years thru trades, i had an extra set of halogen housings with another to fix my cracked stock hid housing.

Me being me, they allll came apart lol

After seeing what was salvageable between all the headlight housings ive sucessfully have 1 hid housing n 1 halogen.

At 1st i was going to be retrofitting my hid housings with quad projectors. But after actually breaking them down and seeing the differences between the 2 i decided to retrofit halogen housing and be able to sell the hid housings. Theres no need to trash nice expensive headlights when halogen housings are the same. just different bowl and wiring + ballast.

I also have a video on youtube explaining the differences between halogen and hid housings for gen 2.

Now to the fun stuff... I kno for a fact i wanted clear corners on my headlights.

Amber/orange was definatly messin up my flow on how i wanted my car to look.

shout out to Manoli 4 the insight.

the reflector lens is behind that black plate with the l.e.d window. 2 strips of sealant hold the plate on. You can cut them off, and jb weld back on. no problem.

material used. plastic ceiling light panel. think 4x2ft sheet.

Next was the switchback halo install on both sets of headlight bezels (inside plastic trim)

Amazon.com: Mihaz Color White-Amber LED DRL Tube Light Car Switchback Soft FluxBeam with Signal-Sync for Headlights and Grills: Automotive

went with 2x pair of these per set.

Install easy... once u get tubes. u peel both ends off n pull led strip right out of the silicone tube. that way your able to mold a nice tight oem effect.

Then once tubes are all shapped up and look proper you can cut led strip and slowly feed it back in tubes. strips are cutable every 3 leds.

Picture has said clear corner and cover

also something i wanted to point out is with these specific led tubes, the top (opposite frm mounting hardware supplied) has most output.

And if you look real closely at the low beam circle you can see i mounted brackets to face out. instead of inside., firing toward one another. but later on my second set. I ditched mounting hardware and just siliconed everything in. less tedious.

Now on to the wiring and making it all work.

ive came up with a nice detailed diagram of how to wire 2 relays (5pin but only use 4)

1 thing that I MUST!!!!! LET YOU KNOW!!!!

using the cheap brand of switchback bulb that i got. with the halo rings/tubes will not work together. lol

havent pinpointed it. turn signals all fuction in sequence and halos take over as daytime running light DRL

Even when i had halos running on seperated 12v. nothing. same result. even wired up relays with different 12v source n same. so theres gotta be feedback somewhere. its probably super simple.

switchback bulb by itself. wrks flawless... halos n tubes wrk flawless. them together? lol not so much but im totally digging the outcome. its only a tiny flaw in my eyes.

now this is the led that goes behind clear corner. i figured. hey. its got to be white. reflector was super amber. but no. you can either not use it at all... or you can do like i am n solder in white micro leds.

i need to get full done, done pictures of it all but last minute led swap kinda held me up lol.

I have this video so far of the overall operation without the led conversion here

Now i suppose we can get on to the real fun part. the quad projector project.

Welllll..... wasnt fun for me.

taking the bowl out and trying to use wat i can stock wise to have my adjusters work was a must.

I started makin room to fit projectors.

Started with 2.5 frm the retrofit source. believe its acme h1 bi-xenon

neck didnt fit at all so hada make room for that

after cuting out the center on high beam bowl, projector fits fine. bolt actually locks in frm backside and u twist on. i finally threw some jb weld jus to be sure on inside of bowl.

now on to the low beam. FDR n I have been noticing how kinda the low beam actually sits lower. u can see now bttr with projectors in

I also threw on the lens to test fit that high beam projector. kind of stuck out but i got clearance with no touching. hopefully ill be alright. i dont use high beams much anyway.

Big bummer on low beam.really wasnt gona stop me now. I guess nxt step would 1. get it to an ideal looking location inside bezel and 2. try n be level with high beam

so that stock adjusters can be used sucessfully

After jus looking at the bowl i knew making a plate to mimic stock adjusters would be best to fit n lift projector up. but still be even

This is wat i came up with. made a plate that fit inside of bowl. i had also cut bowl at bottom to line up straight because of the angle bowl is originally at would have projector aimed high.

i also cut backside of bowl to give me room to wrk and figure rear mount location.

And i j.b welded the Bleeep out of the plate.

Lmfao of course inside as well.

And after

Id have to say im much more happier...

so i get a cheap hid h1 kit to wire everything up n check cutoffs before i seal everything all up.

So far everything has been by eye and done in the house... found an extra set of h.i.d ballast covers n they work well for me.

now to check it all out.

I know, I know. dont laugh. it was all an eye ball. but so far thats where i stand. high beam n low beam are dead on. just need to rotate my low beams so cutoff is nice an crispy.

Stay tuned for part 2.