myfirstlincoln

Dedicated LVC Member

So my 2003 Lincoln has gone through a rejuvenation period over the last year or so.

Anyway, I also decided to order the magnaflow direct fit cat system. I've included a pic. So here is the story and hopefully this makes sense:

I took the system to mechanic to have it installed. He called me and said there was an issue - I'm going to explain this to the best of my ability and hopefully someone can offer some ideas/suggestions. Basically what seems to be happening is that the flange on the new system (which bolts to the old manifold) is too large and when pushed all the way up, sits flush with the flare. On the old system (which was already out of the car) the flange sits about .5 inches below the flare itself (when pushed all the way up) so when it bolts to the manifold, it kinda pulls it/pinches it. The flange on the Magnaflow system has a lot of play (as it is much looser around the pipe) where the flange on the stock system freely moves on the pipe, but is much tighter.

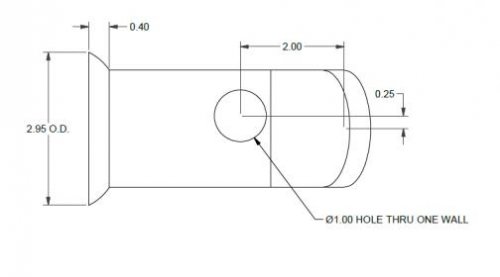

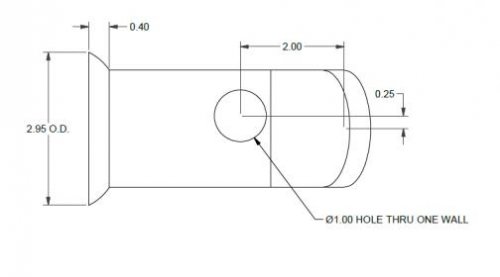

Anyway, I called magnaflow and told them that either the diameter of the flange is too wide so it can ride all the way up the pipe and sit flush with the flare or the flare doesn't start soon enough/isn't large enough. They sent me the pics of the dimensions (which I have included). My mechanic looked at the pics and measured the system I have and he basically said they were fairly accurate. He did say the flare was slightly smaller than the dimensions provided and the flange was slightly larger than the dimensions provided, but not by much at all. If the new system comes (which is currently shipped and on its way) and it's the same as the old system, I'm still in the same boat.

The car is basically sitting there as I wait for the new system to arrive rather than having them reinstall all the old exhaust just to remove it again. I am hoping the new system solves the problem, but to be honest, I kinda think I'm gonna run into the same problem.

If you look at the image below, I think the flange should stop where it says "0.40" but the flange is so wide around the pipe that it rides all the way up to the end of the flare.

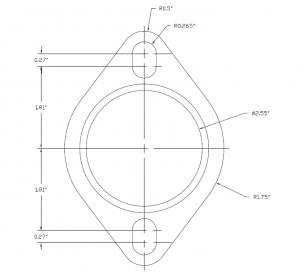

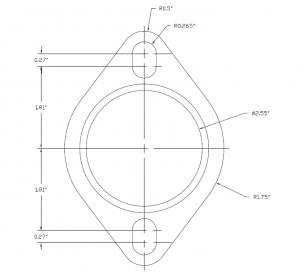

Flange:

If the new system shows up and I have the same problem, do you think I should just weld the flange on? Or weld something on the pipe to prevent the flange from riding up around the flare? Any other thoughts? THANKS!

Anyway, I also decided to order the magnaflow direct fit cat system. I've included a pic. So here is the story and hopefully this makes sense:

I took the system to mechanic to have it installed. He called me and said there was an issue - I'm going to explain this to the best of my ability and hopefully someone can offer some ideas/suggestions. Basically what seems to be happening is that the flange on the new system (which bolts to the old manifold) is too large and when pushed all the way up, sits flush with the flare. On the old system (which was already out of the car) the flange sits about .5 inches below the flare itself (when pushed all the way up) so when it bolts to the manifold, it kinda pulls it/pinches it. The flange on the Magnaflow system has a lot of play (as it is much looser around the pipe) where the flange on the stock system freely moves on the pipe, but is much tighter.

Anyway, I called magnaflow and told them that either the diameter of the flange is too wide so it can ride all the way up the pipe and sit flush with the flare or the flare doesn't start soon enough/isn't large enough. They sent me the pics of the dimensions (which I have included). My mechanic looked at the pics and measured the system I have and he basically said they were fairly accurate. He did say the flare was slightly smaller than the dimensions provided and the flange was slightly larger than the dimensions provided, but not by much at all. If the new system comes (which is currently shipped and on its way) and it's the same as the old system, I'm still in the same boat.

The car is basically sitting there as I wait for the new system to arrive rather than having them reinstall all the old exhaust just to remove it again. I am hoping the new system solves the problem, but to be honest, I kinda think I'm gonna run into the same problem.

If you look at the image below, I think the flange should stop where it says "0.40" but the flange is so wide around the pipe that it rides all the way up to the end of the flare.

Flange:

If the new system shows up and I have the same problem, do you think I should just weld the flange on? Or weld something on the pipe to prevent the flange from riding up around the flare? Any other thoughts? THANKS!