You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your Mark VIII today?

- Thread starter Blkdvll

- Start date

thaywood

Dedicated LVC Member

View attachment 828466808 I know a lot of you have Mustangs. Saw this mod and thought you might like to see it

That's just wrong...

chargerxr

Dedicated LVC Member

gearhead, check your differential bolts/bushings. That is a likely cause of a clunk in the driveline.

Sapperfire

Dedicated LVC Member

That's just wrong...

Saw a Monster'ed out 98 Conti the other day in Dallas but couldn't get a pic of it.

dnsherrill

Dedicated LVC Member

at Gearhead, what do you need for the center console? I have a 94 black that's in decent condition; I'm otp Atl...NW...come get it

gearhead291

Active LVC Member

Grab the rear U-joint and push up and down. See if there's any slop in the Diff.

The trans mount can hide its crack very well, you'll need to take a small pry bar and stick it in where you can lift up on the tail of the trans to see if it's cracked or not

If it turns out to be the trans mount, I highly suggest the Energy Suspension unit from Summit Racing for the T-birds

thanks guys, it was dark when i got off work but im going to get under it in the morning and see if i can figure it out. ill be really happy to have it fixed, its really harsh.gearhead, check your differential bolts/bushings. That is a likely cause of a clunk in the driveline.

well the console itself is fine, and the hinge is still there, the lid is just completely broken/gone where it connects to the hinge. so i just need a lid, that would be sweet if you have one though ! ill send you a message.at Gearhead, what do you need for the center console? I have a 94 black that's in decent condition; I'm otp Atl...NW...come get it

ONLYTONY

Dedicated LVC Member

Just spent 1/2 a day at DMV getting plates for CE-2. Tried yesterday, but gave up. 46 people waiting X 5 min is toooo long for me to wait. The DMV here is so slow, they tell you (on line) how long the wait is at each location. I'm glad that job is done.

Sapperfire

Dedicated LVC Member

I'm glad we get plates from the Tax office and not the DMV

Lownslowlsc

Dedicated LVC Member

On my way home from work and guess what happens? Yup yup, another misfire. 3rd time in 4 months, this time number 7 and baaad. Wish I knew which two I haven't replaced yet so that I could just replace them with the 2 remaining 75k spares. At this rate it shouldn't be long until I find out.

Sapperfire

Dedicated LVC Member

On my way home from work and what happens? Yup yup, another misfire. This time number 7 and badd. Wish I knew which two I haven't replaced yet so that I could just replace them with the 2 remaining 75k spares. At this rate it shouldn't be long until I find out.

Flip flop 6 and 7 coils, reset code, drive til next fmisfire code sets, read code, replce coil

Lownslowlsc

Dedicated LVC Member

Flip flop 6 and 7 coils, reset code, drive til next fmisfire code sets, read code, replce coil

I replaced it once I got home so all is well.

Never get any codes though, I just use a good spare coil and swap each one until it goes away. Easy peasy. Thanks though.

thaywood

Dedicated LVC Member

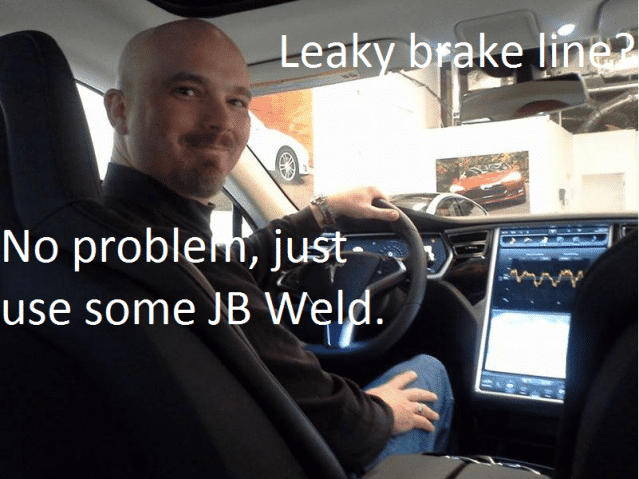

Well...that brake line I spliced together a while back started leaking again this morning  Looks like I'll be tackling the job this weekend. It's gonna be loads of fun.

Looks like I'll be tackling the job this weekend. It's gonna be loads of fun.

Lownslowlsc

Dedicated LVC Member

............Well...that brake line I spliced together a while back started leaking again this morningLooks like I'll be tackling the job this weekend. It's gonna be loads of fun.

thaywood

Dedicated LVC Member

............

:lol: Believe it or not, that JB weld held up for a couple of months. I ended up actually cutting the line and splicing in a piece of line with couplers. One of the couplers is leaking. It'll be fixed this weekend.

Lownslowlsc

Dedicated LVC Member

:lol: Believe it or not, that JB weld held up for a couple of months. I ended up actually cutting the line and splicing in a piece of line with couplers. One of the couplers is leaking. It'll be fixed this weekend.

Oh lord, I didn't know you actually used Jb weld to fix a brake line leak.

thaywood

Dedicated LVC Member

Oh lord, I didn't know you actually used Jb weld to fix a brake line leak.

dnsherrill

Dedicated LVC Member

will you need to bleed the abs pump after the line is replaced?

No I did not use the JB weld to "fix" the brake line leak. I used it to band-aid the leak so I could drive the car because it was all I had to drive at the time. I "fixed" it with a spliced in hard line. Derp...

That is a stupid and dangerous thing to do. I'm gonna assume your "fix" was compression fittings. That's another stupid and dangerous thing to do. And also illegal here in Wisconsin.

dnsherrill

Dedicated LVC Member

----...illegal here in Wisconsin.

that's enforced how...? ex.when a mech sees it, he calls five-o who comes and seizes your car/takes criminal to pokey??

----

are block heaters illegal in Wis. like in NJ?

:dj:

thaywood

Dedicated LVC Member

will you need to bleed the abs pump after the line is replaced?

Nope. It didn't lose that much fluid. Just did a regular brake bleed.

That is a stupid and dangerous thing to do. I'm gonna assume your "fix" was compression fittings. That's another stupid and dangerous thing to do. And also illegal here in Wisconsin.

I'll admit the JB Weld band-aid wasn't the best idea. But it was all I had in a pinch. Compression fittings, on the other hand, work just find. They're the same kind of fittings that virtually all brake lines use on just about every car I've ever seen. It's an easy fix that I and many others have done a hundred times in the past. Why would it be illegal? Brake lines are coupled together at several points on all cars.

----

that's enforced how...? ex.when a mech sees it, he calls five-o who comes and seizes your car/takes criminal to pokey??

----

are block heaters illegal in Wis. like in NJ?

:dj:

Block heaters are legal here. But if you have any of inspection done on a vehicle here, it will fail if there is a compression fitting anywhere on the brakes. If you are in a major accident and the state inspects your vehicle and they find a brake line, you're gonna gonna be found liable. If a person installs one, it fails and some one dies, the installer could be charged with negligent homicide.

Nope. It didn't lose that much fluid. Just did a regular brake bleed.

I'll admit the JB Weld band-aid wasn't the best idea. But it was all I had in a pinch. Compression fittings, on the other hand, work just find. They're the same kind of fittings that virtually all brake lines use on just about every car I've ever seen. It's an easy fix that I and many others have done a hundred times in the past. Why would it be illegal? Brake lines are coupled together at several points on all cars.

JB Weld on a brake line isn't " not the best idea" it's blatant stupidity. Compression fittings do work fine, for low pressure application. They are not designed to hold the 2-3000PSI generated by the brakes of a car. Brake lines are not coupled together with compression fittings, they are joined together with brake line unions. Two brake line nuts and a union might look like a compression fitting to some one who doesn't know any better, but they are not the same. there is a reason why they don't have racks of compression fittings next to the racks of brake lines. Brake lines come with fittings on them for a reason.

Q:

what is the psi for dorman 785-302 compression fitting

Asked on 9/14/2013 by ben from bellaire ,oh

Know the answer? Answer this question

1 answer

CUSTOMER CARE

A:

Dorman - Autograde Compression Fitting-Union-3/16 Inch -Part No. 785-302, there are compression connectors that may use a single-piece design or a plastic gripper in place of ferrules to help maintain a proper seal. Each compression connector, however, includes a compression nut to accomplish the connection. Most standard plastic compression fittings will maintain a seal up to 50 psi, while metal compression fittings may provide a reliable seal up over 200 psi to 220 psi. For any further assistance, please feel free to call us at: 1-877-238-2623 or visit the nearest Advance Auto Parts store and one of our Parts Pros will gladly assist you with any questions or concerns you may have.

Sapperfire

Dedicated LVC Member

My original remote had a chip in the case and buttons were slightly worn some.

Ordered this one for $12, got the new long range Memory 1 transmitter , case , and the Factory buttons

Lownslowlsc

Dedicated LVC Member

JB Weld on a brake line isn't " not the best idea" it's blatant stupidity. Compression fittings do work fine, for low pressure application. They are not designed to hold the 2-3000PSI generated by the brakes of a car. Brake lines are not coupled together with compression fittings, they are joined together with brake line unions. Two brake line nuts and a union might look like a compression fitting to some one who doesn't know any better, but they are not the same. there is a reason why they don't have racks of compression fittings next to the racks of brake lines. Brake lines come with fittings on them for a reason.

I'm pretty sure he meant to say unions.

They're the same kind of fittings that virtually all brake lines use on just about every car I've ever seen.